Solar LED street lights are widely used in urban and rural lighting due to their energy efficiency and ease of installation. However, light decay remains a critical issue affecting their performance and lifespan. Light decay, or the gradual reduction in LED luminous efficiency, not only diminishes brightness but also increases maintenance costs. This article explores the causes of solar LED street light decay and proposes effective solutions.

The Nature and Causes of Light Decay

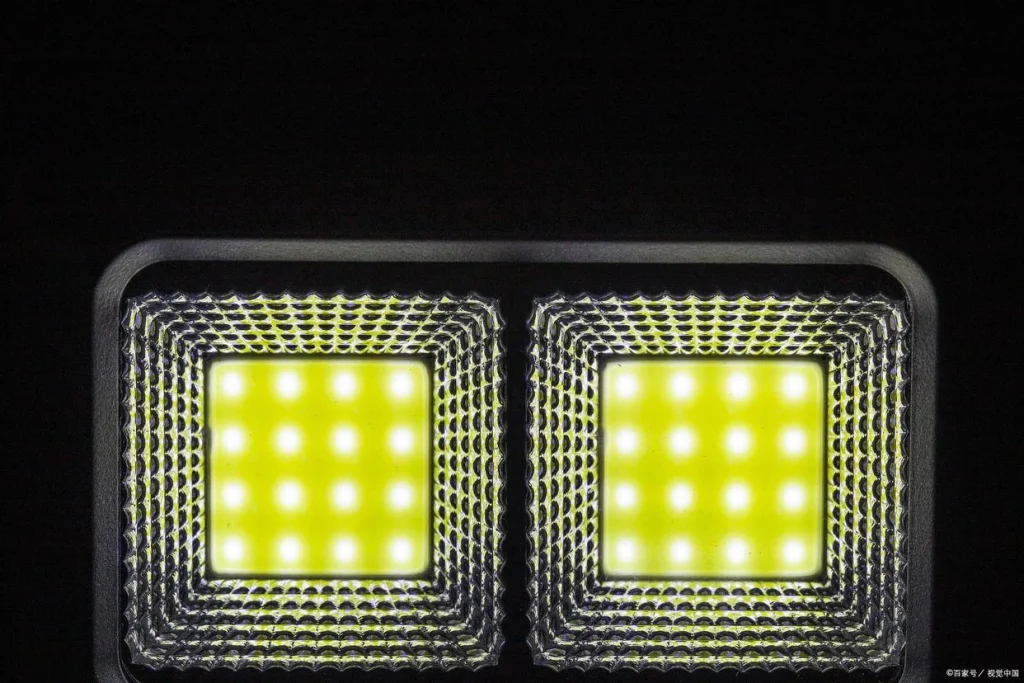

Theoretically, LED photoelectric conversion efficiency can reach 54%, but due to limitations in materials and manufacturing processes, actual efficiency is typically around 30%. The unconverted energy manifests as heat energy, primarily through lattice vibrations caused by non-radiative recombination. This heat is the primary internal factor contributing to light decay. Specifically, the following factors exacerbate light decay:

- Chip Degradation: Poor contact between the LED chip and the bracket, or inadequate thermal conductivity of the bracket, leads to heat accumulation, accelerating chip performance decline.

- Material Aging: Yellowing of epoxy resin and phosphor degradation (especially in white LEDs) significantly reduce light output efficiency.

- Inefficient Heat Dissipation: Poorly designed heat dissipation modules fail to remove heat effectively, causing elevated junction temperatures and shortening LED lifespan.

Additionally, battery light decay is a unique issue for solar LED street lights, where the electrical output from received light diminishes. Combined with light decay, this makes it challenging to maintain initial brightness levels.

The Importance of Heat Dissipation Technology

Heat dissipation is central to addressing light decay. Solar LED street lights have significantly higher power requirements than household lighting, necessitating advanced heat dissipation modules. Bitpott has invested heavily in heat dissipation technology, optimizing module designs to ensure rapid heat transfer. For instance, using high-thermal-conductivity materials and scientifically engineered structures effectively lowers LED junction temperatures, extending service life.

However, many solar street lights suffer from suboptimal heat dissipation due to:

- Inappropriate Material Selection: Iron brackets, for example, have poor thermal conductivity, hindering heat dissipation.

- Inadequate Protective Coatings: Some heat dissipation modules lack proper surface treatments, making them susceptible to corrosion from prolonged exposure to weather.

- Design Flaws: Insufficient contact area between the heat dissipation module and the LED chip reduces heat transfer efficiency.

To address these issues, Bitpott employs innovative heat dissipation solutions, such as baked enamel coating for modules. This cost-effective technique provides excellent protection against corrosion without significantly impeding heat transfer. In contrast, traditional anodizing treatments, while offering some protection, have shorter lifespans, are prone to oxidation and discoloration, and incur higher maintenance costs.

Impacts of Light Decay on Solar Street Lights

Light decay not only reduces brightness but also has broader implications for solar street light performance. When LED luminous efficiency decreases, the lights may fail to meet nighttime illumination needs, compromising road safety. Additionally, light decay shortens the lifespan of the fixtures, increasing replacement and maintenance costs for solar street lights.

For instance, some street lights operating under continuous high loads experience prolonged high junction temperatures due to poor heat dissipation, leading to rapid chip degradation. In white LEDs, phosphor degradation further accelerates light decay, causing noticeable brightness reduction in a short period.

Optimization Strategies and Future Trends

To effectively mitigate light decay, the solar street light industry can adopt the following improvements:

- Advanced Heat Dissipation: Develop materials with superior thermal conductivity, such as aluminum-based composites or graphene heat-dissipation layers, and optimize module structures.

- Improved Protective Coatings: Promote baked enamel coatings and explore more durable surface treatments to extend the lifespan of heat dissipation modules.

- Enhanced Chip Design: Improve contact between LED chips and brackets to reduce thermal resistance and enhance high-temperature resilience.

- Smart Monitoring Systems: Integrate temperature and light decay monitoring technologies to adjust street light operations in real time, minimizing overheating risks.

Bitpott has made initial strides in these areas, with products combining efficient heat dissipation and durable protective coatings to significantly reduce light decay rates. Looking ahead, advancements in new materials and smart technologies promise further improvements in the performance and longevity of solar LED street lights.

Conclusion

The causes of solar LED street light decay are multifaceted, encompassing chip degradation, material aging, and inadequate heat dissipation. By optimizing heat dissipation technology, improving protective coatings, and refining chip designs, light decay can be effectively mitigated, extending the lifespan of street lights. The industry should continue investing in research and development to explore more efficient solutions, contributing to the advancement of sustainable lighting.

Leave a Reply