With the popularization of renewable energy and the promotion of green living, small solar lights, as an energy – saving and environmentally – friendly lighting solution, have attracted increasing attention globally. As an enterprise dedicated to the manufacturing of small solar lights, we are well aware that every link from product design to market application requires meticulous attention to meet diverse customer needs and stand out in the competition. This article comprehensively analyzes the manufacturing methods of small solar lights from multiple key aspects, including product design, selection of solar panels, choice of batteries, circuit design, production process, quality certification, and market application.

I. Product Design: The Integration of Aesthetics and Function

The design of small solar lights is the starting point of the manufacturing process, directly determining the product’s market positioning and user experience. In the design stage, we first conduct differential planning according to the needs of application scenarios. For example:

- Garden Lighting: The appearance of the lamp needs to focus on decoration, with a moderate size and an elegant shape (such as an antique lantern or a modern minimalist style) to blend into the garden environment, while ensuring that the lighting range meets daily usage requirements. Just like a garden solar light launched by the Bitpott brand, it adopts a retro lantern shape with exquisite carved designs on the lampshade. It not only provides warm lighting but also becomes a unique decorative landscape in the garden. Its lighting range has been carefully calculated to effectively illuminate the leisure area of the garden.

- Emergency Lighting: Emphasize portability and durability. Design a compact lamp body that is convenient to carry or install quickly, and be equipped with a high – brightness light source to deal with emergencies.

- Outdoor Decoration: The shape of the lamp needs to highlight artistic sense, such as string lights or creative geometric designs, which not only provide basic lighting but also enhance the aesthetic feeling of the environment.

When achieving the balance between aesthetics and function, we also need to consider the feasibility of the production process. For instance, complex shapes may increase mold costs. Therefore, the design team needs to collaborate with the process department to select materials (such as ABS plastic or aluminum alloy) and structures that are easy to process, ensuring cost control. In addition, the protection level of the lamp (such as IP65) needs to be designed according to the outdoor use environment to ensure water – proof and dust – proof performance.

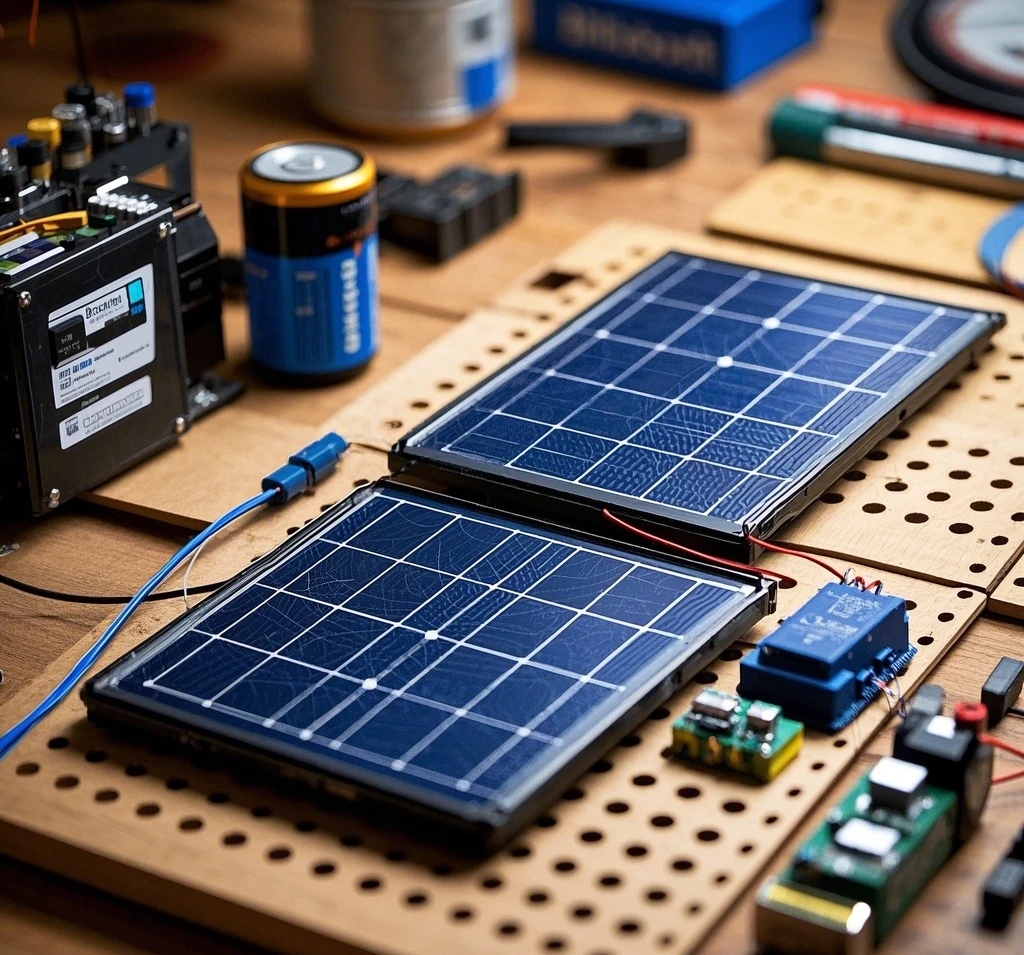

II. Selection of Solar Panels: The Core of Efficient Energy Collection

Solar panels are the energy source of small solar lights, and their performance directly affects the charging efficiency and use stability of the lights. When selecting, we comprehensively consider the following factors:

- Lighting Conditions: For areas with sufficient sunlight (such as tropical regions), monocrystalline silicon solar panels with relatively high conversion efficiency can be selected; while in areas with weak sunlight (such as high – latitude regions), polycrystalline silicon panels are a better choice due to their lower cost and better response to weak light.

- Energy Conversion Efficiency and Power Consumption Matching: Calculate the output power of the solar panel according to the power requirements of the lamp (such as 3W – 10W for LED lights). For example, a 5W lamp is equipped with a solar panel of at least 6W to ensure normal charging even on rainy days.

- Material and Specification: Monocrystalline silicon panels have high efficiency (18% – 22%) and a long service life, but the cost is relatively high; polycrystalline silicon panels have slightly lower efficiency (15% – 18%) but are more economical. We select appropriate materials according to the target market positioning and ensure that the size of the panel is coordinated with the overall proportion of the lamp.

Through accurate selection, we ensure that solar panels can collect energy efficiently and stably in different environments, providing reliable support for the lights.

III. Battery Selection: The Trade – off between Performance and Life

As an energy storage unit, the battery determines the usage duration and durability of the lamp. In battery selection, we focus on the following key points:

- Usage Duration and Capacity: For garden lights, they need to support 6 – 8 hours of lighting, and the capacity is usually 2000 – 4000mAh; emergency lights may require a larger capacity to cope with long – term use.

- Number of Charge – Discharge Cycles: Lithium – ion batteries (such as Li – ion or LiFePO4) can have a cycle life of 1000 – 2000 times, which are suitable for high – end products; nickel – metal hydride batteries have about 500 charge – discharge cycles and are relatively low – cost, suitable for the low – end market.

- Performance and Safety: Lithium – ion batteries have a high energy density and are lightweight, but they need to be equipped with over – charge and over – discharge protection circuits to ensure safety; nickel – metal hydride batteries have higher safety, but their performance decays significantly in low – temperature environments.

- Cost Control: On the premise that the performance meets the requirements, we give priority to choosing battery types with high cost – performance, and reduce costs through bulk purchases.

By scientifically matching the battery type with the application scenario, we ensure that the product takes into account performance, life, and economy.

IV. Circuit Design: The Key to Intelligence and Energy Conservation

Circuit design is the “brain” of small solar lights, responsible for the efficient management of energy and the intelligent realization of functions. In the design, we focus on the following aspects:

- Efficient Charging Management: Adopt MPPT (Maximum Power Point Tracking) or PWM (Pulse Width Modulation) technology to optimize the charging efficiency of solar panels to batteries, ensuring maximum energy utilization.

- Stable Power Supply: Design a constant – current circuit to ensure the stable brightness of LED lights and avoid light decay caused by battery voltage fluctuations.

- Intelligent Control: Integrate a light – controlled module (charging during the day and lighting at night) and a time – controlled function (such as 4 – hour/6 – hour mode). Some high – end products also add human – body induction or remote control to enhance the user experience and energy – saving effect.

Through reasonable circuit layout and component selection, we not only improve the intelligence level of the product but also extend its overall service life.

V. Production Process: Emphasizing Both Efficiency and Quality

The production process covers the entire process from raw material procurement to final inspection, which is the guarantee for manufacturing high – quality solar lights. We strive for excellence in each link:

- Raw Material Procurement: Cooperate with high – quality suppliers to ensure the stability of solar panels, batteries, and shell materials.

- Component Processing: Use automated equipment (such as injection molding machines, laser cutting machines) to improve processing accuracy and reduce manual errors.

- Lamp Assembly: Improve efficiency through assembly line operations, and set quality inspection points at key nodes (such as welding and sealing).

- Product Testing: Include light – effect testing, waterproof testing, and charge – discharge performance testing to ensure that each lamp meets the design standards before leaving the factory.

By optimizing the production process, we effectively improve production efficiency and control the defective rate below 1%, significantly reducing costs.

VI. Product Quality and Certification: The Passport to Market Access

Product quality is the cornerstone of an enterprise’s reputation. Small solar lights need to meet a number of domestic and international standards, such as:

- Domestic Standards: GB/T 24908 (Performance Requirements for LED Lamps), CCC Certification.

- International Standards: IEC 61215 (Solar Module Testing), CE, RoHS Certification.

Obtaining these certifications not only ensures that the product meets safety and environmental protection requirements but also paves the way for entering the international market and enhances brand competitiveness.

VII. Market and Application Areas: Diverse Prospects

Small solar lights, with their portability and environmental friendliness, show broad prospects in multiple fields:

- Civil Market: Lighting for family gardens and homestay terraces, with the demand 偏向 ing aesthetics and practicality. Some products of the Bitpott brand, due to their stylish and beautiful design and stable lighting effect, have won the favor of many consumers in the civil market and become a powerful assistant for families to create a warm outdoor space.

- Commercial Market: Landscape lighting for hotels and indicator lights for scenic spots, emphasizing durability and decoration.

- Special Scenarios: Field operations and disaster emergency lighting, requiring high reliability and portability.

For different markets, we analyze demand trends (such as intelligence and low – cost) and flexibly adjust product strategies to seize market opportunities.

Conclusion

The manufacturing of small solar lights is a systematic project, involving the comprehensive coordination of design, material selection, circuit, production, and market application. As a professional manufacturing enterprise, we continuously optimize product performance and cost – effectiveness through scientific planning and technological innovation to meet the needs of global customers. In the future, with the progress of solar technology and the growth of market demand, small solar lights will surely play a more important role in the field of green lighting.

Leave a Reply